With the rapid growth of the global livestock and poultry industry, driven by increasing population, rising demand for high-quality protein, and the modernization of agricultural practices, efficient and standardized feed processing has become more important than ever.

The feed industry, as the cornerstone of the livestock sector, is under constant pressure to enhance productivity, reduce costs, and ensure the safety and nutritional value of feed products. Feed manufacturers and farm owners are increasingly turning to advanced equipment to address these challenges, and among these solutions, the animal feed pellet making machine stands out as a pivotal piece of equipment. It plays a vital role in transforming raw feed materials—such as corn, soybean meal, wheat bran, and forage—into high-quality, nutritionally balanced pellets.

Whether used independently by small-scale farmers or integrated as part of a complete animal feed production line in large industrial facilities, animal feed pellet machine is indispensable for modern, large-scale animal feed production. Its widespread adoption has not only revolutionized feed processing workflows but also contributed significantly to the sustainability and profitability of the global livestock industry.

1. What Is an Animal Feed Pellet Making Machine?

An animal feed pellet making machine, also known as a feed pelletizer, is a specialized piece of equipment engineered to convert powdered, granular, or mixed feed materials into dense, uniform, and compact feed pellets through mechanical compression. These pellets are tailored to meet the nutritional requirements of various animal species, including poultry (chickens, ducks, geese, turkeys), livestock (cattle, sheep, pigs, goats), and aquatic animals (fish, shrimp, crabs).

The core working principle of a feed pelletizer involves feeding prepared raw materials into a compression chamber, where a pair of rollers presses the materials through small holes in a circular die. The combination of pressure and friction generates heat, which gelatinizes starch in the feed, improves the binding quality of the pellets, and enhances their digestibility.

Compared with traditional mash feed (unprocessed powdered feed), pellet feed produced by an animal feed pellet making machine offers a multitude of advantages that have driven its widespread adoption.

Firstly, pellet feed has better digestibility. The heat and pressure during the pelletizing process break down complex nutrients, such as starch and fiber, making them easier for animals to absorb. Studies have shown that pellet feed can improve the feed conversion ratio (FCR) by 5% to 15% compared to mash feed, depending on the animal species and feed formula.

Secondly, it reduces feed waste significantly. Mash feed is prone to segregation during transportation and feeding, with animals often selecting preferred components and leaving others, leading to nutritional imbalances and waste. Pellets, on the other hand, are uniform in composition, ensuring that animals consume all nutrients in each bite. This not only reduces waste by 10% to 20% but also helps maintain consistent growth rates among livestock and poultry.

Thirdly, pellet feed offers improved hygiene. The heat generated during pelletization (typically between 70°C and 90°C) can kill harmful bacteria, such as Salmonella and E. coli, and reduce the presence of mold spores, thereby lowering the risk of animal diseases and improving the safety of animal products (meat, eggs, milk) for human consumption. Fourthly, pellet feed is easier to transport and store. The compact structure of pellets reduces their volume by 20% to 30% compared to mash feed, minimizing storage space requirements and transportation costs. Pellets are also less susceptible to moisture absorption and caking, extending their shelf life. With the rapid development of industrial farming and the increasing emphasis on food safety and production efficiency, the animal feed pellet making machine has become an essential component in modern feed mills, large-scale farms, and even small-scale agricultural operations aiming to improve their productivity.

2. Role of Animal Feed Pellet Making Machine in Animal Feed Production Line

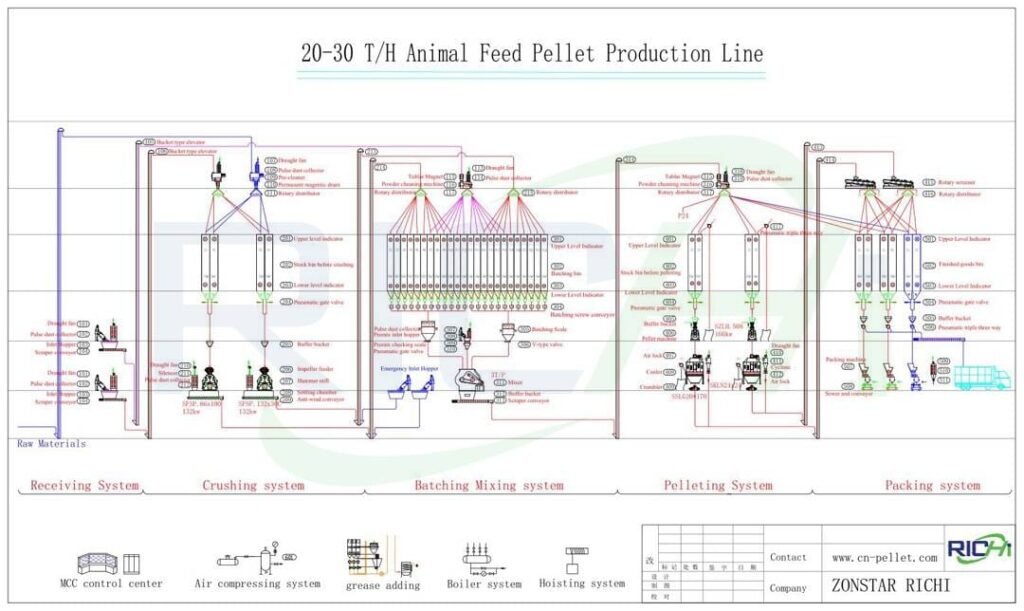

In a complete animal feed production line, the animal feed pellet making machine occupies a central and irreplaceable position, acting as the “heart” of the entire production process. A standard, fully functional animal feed production line consists of several interconnected systems, each performing a specific role in transforming raw materials into finished feed products. Understanding the integration of the pellet making machine within this line is crucial for appreciating its importance.

(Related Post: https://pelletisingmachine.com/animal-feed-production-line/)

The first stage in the production line is the raw material crushing system. Raw materials, such as corn, soybeans, and wheat, are usually in large granular form and need to be crushed into fine powder to ensure uniform mixing and efficient pelletization. Crushers (hammer mills or roller mills) reduce the particle size of raw materials to a range of 0.8mm to 2.0mm, depending on the type of feed and animal species. Next is the feed mixing system, where the crushed raw materials are blended with essential additives, such as vitamins, minerals, amino acids, and medicinal ingredients, according to a precise formula. Uniform mixing is critical to ensuring that each pellet contains the correct nutritional composition, and specialized mixers (ribbon mixers or paddle mixers) are used to achieve this.

Following mixing, the material is fed into the animal feed pellet making machine—the core pelletizing system. It is at this stage that the loose powder is converted into dense pellets. The performance of the pellet making machine directly determines the quality of the final product (e.g., pellet hardness, uniformity, and nutritional retention) and the overall production efficiency of the line. After pelletization, the pellets are hot and moist, so they enter the pellet cooling and screening system. Coolers (counterflow coolers or crossflow coolers) reduce the temperature of the pellets to near room temperature, which helps maintain their shape and prevents mold growth. Screening machines then separate broken pellets and fine powder from products; the rejected materials are usually recycled back to the pellet making machine for reprocessing.

The final stage is the packaging system, where the cooled and screened pellets are weighed and packed into bags or bulk containers for storage and transportation. The animal feed pellet making machine’s compatibility with other systems in the production line is crucial for ensuring a smooth, continuous workflow. A high-performance pelletizer can handle large volumes of material without causing bottlenecks, while a poorly performing one can disrupt the entire production process, leading to reduced output, increased energy consumption, and higher operating costs. Additionally, the pelletizer’s ability to produce consistent, high-quality pellets directly impacts the marketability of the feed product, as farmers and livestock producers prioritize feed that promotes animal health and growth.

3. Types of Animal Feed Pellet Making Machine

The diversity of the global feed industry—ranging from small home farms to large-scale industrial feed mills—has led to the development of various types of animal feed pellet making machines. Each type is designed to meet specific production needs, animal species requirements, and operational scales. Understanding the different types and their characteristics is essential for selecting the right equipment for a particular application.

(1) Small Animal Feed Pellet Making Machine

Small animal feed pellet making machines are specifically designed for small-scale operations, such as home farms, small poultry or livestock breeders, and small feed workshops. These machines are characterized by their compact structure, which allows them to be installed in limited spaces, and their low investment cost, making them accessible to small-scale operators. Most small pelletizers are manually operated or semi-automatic, with simple controls that require minimal technical expertise to use. They typically have a production capacity ranging from 50 kg/h to 500 kg/h, which is sufficient for meeting the feed needs of small herds or flocks.

One of the key advantages of small pellet making machines is their versatility. They can process a wide range of raw materials, including corn, soybean meal, wheat bran, grass meal, and even agricultural by-products, making them suitable for producing feed for various animals. Many small models are also portable, allowing farmers to move them between different locations on the farm. However, due to their small size and lower power, they are not suitable for continuous, high-volume production. They are ideal for operators who prioritize flexibility and low cost over large-scale output.

(2) Commercial Animal Feed Pellet Making Machine

Commercial animal feed pellet making machines are engineered for medium and large feed factories that require continuous, high-capacity production. These machines are usually integrated into fully automatic animal feed production lines, working in tandem with crushers, mixers, coolers, and packaging equipment to form a seamless production workflow. Commercial pelletizers have a production capacity ranging from 1 ton/h to 20 tons/h or more, depending on the model and configuration.

To meet the demands of large-scale production, commercial pellet making machines are equipped with powerful motors, high-quality dies and rollers, and advanced control systems. They are designed for 24/7 operation, with robust construction that ensures durability and reliability. Many modern commercial pelletizers feature automatic feeding, temperature control, and fault detection systems, which reduce the need for manual intervention and improve operational efficiency. The high automation level also ensures consistent pellet quality, even during long production runs. However, commercial pellet making machines require a significant initial investment and higher operating costs (energy, maintenance), making them suitable only for large feed manufacturers with high production volumes.

(3) Animal Feed Pellet Making Machine for Poultry Feed

Poultry (such as chickens, ducks, and turkeys) have specific dietary requirements and feeding habits, which has led to the development of specialized chicken feed pellet making machine. Poultry feed pellets need to be small in diameter (usually 2mm to 4mm), uniform in size, and have good palatability to ensure that young birds can easily consume them. Additionally, poultry feed often contains high levels of starch and protein, which require precise processing parameters to maintain nutritional value.

Poultry feed pellet making machines are optimized with smaller die holes and adjustable compression ratios to produce pellets that meet these requirements. The rollers and dies are designed to generate the right amount of heat to gelatinize starch, which improves digestibility and binding quality. Many of these machines also feature a gentle pelletizing process to avoid damaging heat-sensitive nutrients, such as vitamins and amino acids. Additionally, poultry feed pelletizers often have a higher production speed to meet the large feed demands of commercial poultry farms. The specialized design ensures that the pellets are easy for poultry to eat, reduce waste, and promote healthy growth and egg production.

(4) Animal Feed Pellet Making Machine for Livestock Feed

Livestock, such as cattle, sheep, and goats, are ruminants with a digestive system that can process high-fiber materials, such as hay, straw, and silage. Animal feed pellet making machines for livestock feed production are specifically designed to handle these high-fiber raw materials efficiently. Unlike poultry feed pelletizers, livestock feed pelletizers have larger die holes (usually 6mm to 12mm) to produce larger pellets suitable for ruminant consumption.

These machines are equipped with more powerful rollers and thicker dies to handle the abrasive nature of high-fiber materials. The compression ratio is also adjustable to ensure that the pellets are dense enough to withstand transportation and storage but not too hard for livestock to chew. Additionally, livestock feed pellet making machines often feature a pre-heating system to soften high-fiber materials, making them easier to pelletize and improving digestibility. The ability to process high-fiber by-products, such as corn stover and wheat straw, makes these machines an important tool for reducing feed costs and promoting the utilization of agricultural waste, contributing to the sustainability of the livestock industry.

4. Key Features and Technical Parameters to Consider

Selecting the right animal feed pellet making machine is a critical decision that directly impacts the efficiency, productivity, and profitability of a feed production operation. With a wide range of models and configurations available on the market, buyers need to carefully evaluate key features and technical parameters to ensure that the equipment meets their specific needs. The following factors are essential considerations during the selection process.

Firstly, production capacity is one of the most important parameters to consider. Production capacity is usually measured in kilograms per hour (kg/h) or tons per hour (t/h), and it should match the expected output requirements of the operation. Small-scale farmers or workshops may only need a machine with a capacity of 100-500 kg/h, while large feed factories may require a capacity of 5-20 tons/h or more. Choosing a machine with insufficient capacity can lead to production bottlenecks, while selecting one with excessive capacity can result in wasted energy and higher operating costs.

Secondly, the applicable raw materials should be carefully evaluated. Different pellet making machines are designed to handle different types of raw materials, such as grain-based feeds, high-fiber forages, or aquatic feed materials. Buyers should ensure that the machine can process the specific raw materials they intend to use. For example, if producing livestock feed with high-fiber content, a machine with a robust design and adjustable compression ratio is necessary. Additionally, the machine should be able to handle variations in raw material moisture content, as moisture levels (typically 12%-16% for pelletization) significantly impact pellet quality.

Thirdly, adjustable pellet diameter is a key feature for versatility. Different animal species and age groups require pellets of different sizes. For example, young chicks need 2mm pellets, while adult cattle require 8-12mm pellets. A machine with interchangeable dies allows for easy adjustment of pellet diameter, enabling the production of multiple feed types with a single machine. This is particularly beneficial for small-scale operators who produce feed for multiple animal species.

Fourthly, energy consumption and operational stability are important factors for reducing costs and ensuring continuous production. Energy-efficient machines can significantly lower electricity costs, especially for large-scale operations with continuous production. Operational stability refers to the machine’s ability to run smoothly without frequent breakdowns. Machines with high-quality components, such as hardened steel dies and rollers, and reliable transmission systems, tend to have better stability and longer service life. Buyers should also consider the availability of spare parts and after-sales service, as this can minimize downtime in case of equipment failure.

Fifthly, compatibility with the existing or planned animal feed production line is crucial for integrated operations. The pellet making machine should fit seamlessly into the production line, with matching feed rates and output sizes to ensure a smooth workflow. This includes compatibility with feed conveyors, mixers, coolers, and packaging equipment. Additionally, the machine’s control system should be compatible with the line’s automation system, allowing for centralized control and monitoring.

Finally, animal feed pellet making machine price is a practical consideration for most buyers. Prices vary widely depending on production capacity, automation level, configuration, and brand. Small-scale machines may cost a few thousand dollars, while large commercial models can cost hundreds of thousands of dollars. Buyers should balance price with quality and performance, avoiding the temptation to choose the cheapest option if it compromises reliability or efficiency. It is also important to consider the total cost of ownership, including energy consumption, maintenance costs, and spare parts, rather than just the initial purchase price.

5. Advantages of Using Animal Feed Pellet Making Machine

The adoption of an animal feed pellet making machine offers a wide range of advantages for feed manufacturers, farmers, and the livestock industry as a whole. These advantages extend beyond improved feed quality to include economic, environmental, and operational benefits, making pelletization a preferred feed processing method in modern agriculture.

One of the most significant advantages is the improved feed conversion ratio (FCR). FCR is a key metric in the livestock industry, measuring the amount of feed required to produce a unit of animal weight gain. Pellet feed, due to its improved digestibility and uniform nutritional composition, allows animals to convert feed into body weight more efficiently. For example, in poultry farming, pellet feed can reduce FCR by 8%-12% compared to mash feed, meaning less feed is needed to produce the same amount of meat or eggs. This not only reduces feed costs but also increases the profitability of livestock operations.

Another major benefit is the reduction of feed waste and dust. As mentioned earlier, mash feed is prone to segregation and selective feeding by animals, leading to significant waste. Pellet feed eliminates this problem by ensuring that each bite contains a uniform mixture of all nutrients, reducing waste by 10%-20%. Additionally, pelletization reduces dust levels during feed handling and feeding, which improves the working environment for farm workers and reduces respiratory health risks for both humans and animals. Dust reduction also minimizes the risk of feed dust explosions in large feed mills, enhancing workplace safety.

The use of pellet feed also enhances animal growth performance and health. The improved digestibility of pellet feed ensures that animals absorb more nutrients, leading to faster growth rates, better body weight uniformity, and higher productivity. For example, broiler chickens fed with pellet feed reach market weight 5-7 days earlier than those fed with mash feed. Additionally, the heat treatment during pelletization kills harmful bacteria and mold, reducing the risk of digestive diseases and improving animal health. Healthy animals require fewer antibiotics and medications, which not only reduces production costs but also addresses growing consumer concerns about antibiotic residues in animal products.

Lower storage and transportation costs are another important advantage. Pellet feed has a higher bulk density than mash feed, meaning more feed can be stored in the same space. This reduces the need for additional storage facilities and lowers storage costs. In transportation, the compact size of pellets reduces shipping volume, leading to lower transportation costs per ton of feed. Pellets are also less susceptible to moisture absorption and spoilage, extending their shelf life and reducing losses due to feed degradation.

For large-scale feed manufacturers, the use of animal feed pellet making machines enables standardized production. Standardization ensures that each batch of feed has consistent quality and nutritional composition, which is crucial for building a strong brand reputation and meeting regulatory requirements. Automated pellet making machines allow for precise control of processing parameters, such as temperature, pressure, and pellet size, ensuring that the final product meets strict quality standards. Standardized production also makes it easier to track and trace feed batches, which is essential for food safety compliance.

Finally, the use of animal feed pellet making machines contributes to environmental sustainability. By reducing feed waste, pelletization reduces the amount of resources (grain, water, energy) used in feed production. Additionally, the ability to process agricultural by-products, such as corn stover and wheat straw, into feed pellets promotes the recycling of waste materials, reducing agricultural waste and greenhouse gas emissions. Energy-efficient pellet making machines further reduce the carbon footprint of feed production operations.

6. Maintenance Tips for Animal Feed Pellet Making Machine

Proper maintenance is essential to ensure the long-term stable operation of an animal feed pellet making machine, maintain pellet quality, and prolong its service life. Neglecting maintenance can lead to frequent breakdowns, reduced production efficiency, increased energy consumption, and higher repair costs. The following maintenance tips are recommended for both small-scale and commercial pellet making machines.

Firstly, regularly inspect die and roller wear. The die and roller are the core components of the pellet making machine, and they are subject to constant friction during operation. Over time, this friction causes wear, which can affect pellet quality (e.g., uneven size, poor binding) and reduce production capacity. It is recommended to inspect the die and roller daily before operation, checking for signs of wear, cracks, or damage. The frequency of replacement depends on the type of raw materials processed (abrasive materials cause faster wear) and the operating hours. Typically, dies and rollers should be replaced every 1,000-3,000 operating hours. Additionally, proper cleaning of the die holes after each use prevents clogging, which can affect pellet formation.

Secondly, ensure proper lubrication of moving parts. The moving parts of the pellet making machine, such as the main shaft, bearings, and gears, require regular lubrication to reduce friction and prevent overheating. It is important to use the correct type of lubricating oil or grease recommended by the manufacturer. Lubrication should be performed according to the manufacturer’s schedule—usually every 50-100 operating hours for small machines and daily for commercial machines. Over-lubrication should be avoided, as excess oil can contaminate the feed. Additionally, check for oil leaks regularly and replace worn seals promptly.

Thirdly, control raw material moisture content. Raw materials with too high or too low moisture content can cause problems for the pellet making machine. High moisture content (above 16%) can lead to excessive wear of the die and roller, poor pellet quality (soft, easily broken), and mold growth. Low moisture content (below 12%) can increase energy consumption and cause the pellets to be too hard, affecting digestibility. It is recommended to test the moisture content of raw materials regularly and adjust it as needed, either by adding water or drying the materials.

Fourthly, operate the machine according to the manufacturer’s guidelines. Improper operation is a common cause of machine damage. Operators should be trained to use the machine correctly, including proper startup and shutdown procedures, adjusting processing parameters (temperature, pressure, feed rate) according to the raw materials and desired pellet quality, and avoiding overloading the machine. For commercial machines, it is important to monitor the machine’s operating parameters (temperature, pressure, current) during operation and address any abnormalities promptly. Additionally, avoid feeding foreign objects (such as stones, metal pieces) into the machine, as this can cause serious damage to the die and roller.

Fifthly, perform routine cleaning and maintenance. After each day of operation, clean the machine thoroughly to remove residual feed particles, which can attract pests and cause mold growth. Pay special attention to the compression chamber, die, and roller. Periodically inspect other components, such as the motor, belt drive, and control system, for signs of damage or wear. Tighten loose bolts and nuts regularly to ensure the machine’s stability. It is also recommended to keep a maintenance log, recording the date of maintenance, tasks performed, and any issues encountered. This helps track the machine’s performance and plan for future maintenance or component replacement.

Finally, store the machine properly when not in use. If the machine is not used for an extended period (e.g., during off-seasons), it should be cleaned thoroughly, dried, and lubricated. Cover the machine with a dust cover to protect it from dust and moisture. Store the machine in a dry, well-ventilated area to prevent rust and corrosion.

7. Future Trends of Animal Feed Pellet Making Machine

The global feed industry is undergoing rapid transformation, driven by technological advancements, increasing demand for sustainable and safe food products, and growing pressure to reduce environmental impact. As a key piece of equipment in the feed production process, animal feed pellet making machines are evolving to meet these changing demands. The following trends are expected to shape the future of feed pellet making technology.

Firstly, the integration of intelligent and automated control systems is a major trend. Modern feed manufacturers are increasingly adopting Industry 4.0 technologies to improve operational efficiency and product quality. Future pellet making machines will be equipped with advanced sensors, Internet of Things (IoT) connectivity, and artificial intelligence (AI) algorithms. These technologies will enable real-time monitoring of processing parameters (temperature, pressure, feed rate, pellet quality), automatic adjustment of operating conditions to optimize performance, and predictive maintenance. For example, sensors can detect changes in die and roller wear, alerting operators to replace components before they fail. AI algorithms can analyze data from multiple production runs to optimize feed formulas and processing parameters, improving pellet quality and reducing energy consumption. Remote monitoring and control will also become more common, allowing operators to manage the machine from anywhere, reducing the need for on-site personnel.

Secondly, deep integration with the entire animal feed production line will be a key focus. Future pellet making machines will be designed to work seamlessly with other equipment in the production line, such as crushers, mixers, coolers, and packaging systems, through a centralized control system. This integration will enable fully automated production workflows, from raw material intake to finished product packaging, with minimal manual intervention. For example, the pellet making machine can communicate with the mixer to adjust the feed rate based on the moisture content and particle size of the mixed material, ensuring optimal pelletization. This level of integration will not only improve production efficiency but also enhance the traceability of feed batches, as each step of the production process can be tracked and recorded.

Thirdly, energy-saving and environmentally friendly designs will become increasingly important. The feed industry is under growing pressure to reduce its carbon footprint and energy consumption. Future pellet making machines will incorporate energy-efficient motors, advanced transmission systems, and optimized die and roller designs to reduce energy use. For example, variable frequency drives (VFDs) will be used to adjust the motor speed according to production demand, reducing energy waste during low-load operation. Additionally, machines will be designed to use renewable energy sources, such as solar or wind power, where possible. Environmentally friendly materials, such as biodegradable lubricants and recyclable components, will also be adopted to reduce environmental impact. Furthermore, the ability to process alternative feed materials, such as insect meal, algae, and food waste, into high-quality pellets will be enhanced, promoting the use of sustainable feed sources and reducing reliance on traditional grain-based feeds.

Fourthly, the development of multi-functional machines for different feed formulas will continue. As the livestock industry diversifies, with increasing demand for specialized feeds (e.g., organic feed, medicated feed, aquatic feed), future pellet making machines will be designed to handle a wider range of feed formulas and raw materials. Multi-functional machines will feature interchangeable components, such as dies of different sizes and materials, and adjustable processing parameters, allowing for quick switching between feed types. For example, a single machine could produce both poultry feed and livestock feed by changing the die and adjusting the compression ratio. This versatility will be particularly beneficial for small and medium-scale feed manufacturers who need to produce multiple feed types to meet market demand.

Finally, the focus on improving pellet quality and nutritional retention will drive technological advancements. Future pellet making machines will incorporate new technologies to minimize nutrient loss during processing. For example, low-temperature pelletization technologies will be developed to preserve heat-sensitive nutrients, such as vitamins and probiotics. Additionally, advanced die designs will be used to produce pellets with better water stability, which is crucial for aquatic feed. The use of precision engineering will ensure that pellets are more uniform in size and shape, improving feed intake and digestibility for animals.

( Richi Machinery )

The animal feed pellet making machine is a critical investment for any modern feed producer, whether operating on a small scale or a large industrial level. Its ability to convert raw feed materials into high-quality, nutritionally balanced pellets has revolutionized the feed industry, offering numerous benefits such as improved feed conversion ratio, reduced waste, enhanced animal health, and lower storage and transportation costs. As an integral part of the animal feed production line, the pellet making machine’s performance directly impacts the efficiency, profitability, and competitiveness of feed production operations.

Selecting the right pellet making machine requires careful consideration of production capacity, applicable raw materials, adjustable pellet diameter, energy consumption, operational stability, compatibility with production lines, and price. Proper maintenance, including regular inspection of die and roller wear, proper lubrication, control of raw material moisture, and adherence to operating guidelines, is essential to ensure the machine’s long-term performance and longevity.

Looking to the future, the animal feed pellet making machine will continue to evolve, driven by technological advancements and changing industry demands. Intelligent and automated control systems, deep integration with production lines, energy-saving and environmentally friendly designs, and multi-functional capabilities will be the key trends shaping the development of these machines. As the global livestock industry continues to grow and modernize, the importance of high-quality, efficient feed pellet making machines will only increase, playing a vital role in ensuring the sustainability, safety, and profitability of the feed and livestock sectors.