In the rapidly developing livestock and aquaculture industry, the quality of feed directly determines the growth efficiency, health status and breeding benefits of animals. As a core equipment in feed processing, the animal feed pellet machine for sale has become an indispensable tool for large-scale farms, feed factories and individual breeders due to its ability to convert scattered raw materials into high-quality pellet feed. This article will comprehensively interpret the feed pellet machine, including its application scope, core advantages, working principle, selection skills and investment return, helping you fully grasp the key information of this equipment and improve breeding efficiency.

1. What is a Feed Pellet Machine? Core Function and Working Principle

A feed pellet machine is a professional equipment that processes various feed raw materials (such as corn, soybean meal, wheat bran, grass meal, fish meal, etc.) into uniform granular feed under the action of temperature, pressure and moisture. Its core function is to solve the problems of uneven nutrition, easy waste and difficult storage of traditional bulk feed, and improve the palatability and digestion and absorption rate of feed.

The working principle of the feed pellet machine is relatively simple: first, the mixed powdery raw materials are put into the hopper of the machine; then, the rotating roller and the die in the machine exert high pressure on the raw materials, so that the materials are extruded through the holes on the die to form cylindrical pellets; during the extrusion process, the friction between the roller and the die will generate a certain temperature (usually 70-85 °C), which can not only pasteurize the feed to kill harmful bacteria such as salmonella, but also make the starch in the raw materials gelatinized, which is more conducive to the digestion and absorption of animals. Finally, the formed pellets are cut into uniform lengths by a cutter and then cooled and screened to become finished feed pellets.

2. Wide Application of Feed Pellet Machine: Covering All Types of Breeding Scenarios

The feed pellet machine has strong versatility and can process feed for various animals, covering almost all breeding fields. Whether it is a small family farm or a large-scale industrial feed factory, it can find a suitable model. Its main application scenarios include:

- Poultry feed production: It can process feed for chickens (broilers, layers), ducks, geese, quails, pigeons and other poultry. The produced pellets have moderate hardness and good palatability, which can improve the feed intake of poultry and reduce feed waste.

- Livestock feed production: Suitable for processing pig feed, rabbit feed, etc. The pellet feed processed by the feed pellet machine has balanced nutrition, which can promote the growth and development of livestock and improve the feed conversion rate.

- Ruminant feed production: It can produce high-fiber pellet feed for cattle, cows, sheep, horses, camels and other ruminants. The reasonable processing technology can retain the nutritional components of forage grass and improve the digestion efficiency of ruminants.

- Aquatic feed production: It can process sinking fish feed, floating fish feed, shrimp feed and ornamental fish feed. By adjusting the processing parameters, the density and buoyancy of the pellets can be controlled to meet the feeding habits of different aquatic products.

- Pet feed production: It can also be used to process feed for dogs, cats and other pets, realizing the personalized matching of pet nutrition.

For more details, please click to view:https://www.richimanufacture.com/chicken-feed-production-line/

3. Why Choose a Feed Pellet Machine? Core Advantages of Pellet Feed

Compared with traditional bulk feed, pellet feed produced by a feed pellet machine has obvious advantages, which is also the key reason why more and more breeders choose to use feed pellet machines. The specific advantages are as follows:

3.1 Improve Feed Utilization Rate and Reduce Waste

Pellet feed has a uniform shape and moderate hardness, which can avoid the problem of animals picking and eating raw materials, ensuring that each animal can get a balanced nutrition. At the same time, pellet feed is not easy to scatter, which can reduce feed waste by 5%-10% compared with bulk feed. For large-scale farms, this can save a lot of feed costs every year.

3.2 Enhance Feed Safety and Palatability

During the processing of the feed pellet machine, the high temperature generated by friction can effectively kill harmful bacteria, molds and parasites in the raw materials, reducing the risk of animal diseases. In addition, the high-temperature and high-pressure processing will make the feed produce a special fragrance, which can improve the palatability of the feed and stimulate the feed intake of animals.

3.3 Facilitate Storage and Transportation

Pellet feed has high density and good fluidity, which is convenient for storage and transportation. Compared with bulk feed, it takes up less storage space and is not easy to absorb moisture and agglomerate, which can extend the shelf life of feed. For breeders who need long-distance transportation of feed, using a feed pellet machine to process pellet feed can greatly reduce transportation costs.

3.4 Reduce Breeding Costs and Improve Economic Benefits

Breeders can purchase local raw materials (such as corn, straw, rice bran, etc.) to process pellet feed by themselves, which can save the intermediate links of purchasing commercial feed and reduce feed costs by 300-600 yuan per ton. In addition, some breeders can also carry out feed processing services for surrounding farmers, charging 200-500 yuan per ton of processing fees, which can obtain stable additional income.

3.5 Energy Saving and Environmental Protection, Stable Operation

The modern 1-45T/H feed pellet machine adopts advanced design concepts, such as gear-driven technology, which has the advantages of stable operation, low noise and low energy consumption. At the same time, the machine is equipped with a dust removal device, which can reduce dust pollution during the processing process and meet the requirements of environmental protection. Some high-end models also have an automatic lubrication system and a hydraulic die change system, which are easy to maintain and save labor costs.

4. How to Choose a Suitable Feed Pellet Machine? Key Selection Criteria

There are many types and models of feed pellet machines on the market, with prices ranging from tens of dollars to tens of thousands of dollars. How to choose a suitable feed pellet machine according to your own needs is a problem that every buyer needs to face. The following key selection criteria can help you make a rational decision:

4.1 Determine the Model According to Production Capacity

The production capacity of feed pellet machines varies greatly, ranging from 50 kg/h for small models to 42 t/h for large industrial models. If you are a small family farmer (breeding 100-500 pigs/sheep or 500-5000 chickens/ducks), a small feed pellet machine with a production capacity of 50-500 kg/h is sufficient; if you are engaged in feed processing services or run a medium-sized farm, you can choose a medium-sized model with a production capacity of 500-2000 kg/h; for large-scale feed factories, you need to choose a large feed pellet machine with a production capacity of more than 2000 kg/h.

4.2 Pay Attention to Core Components and Quality

The core components of the feed pellet machine include the die, roller, gearbox and motor, which directly affect the service life and production efficiency of the machine. It is recommended to choose a feed pellet machine with high-quality alloy die and roller, which has good wear resistance and can reduce the frequency of replacement of vulnerable parts. At the same time, the gearbox should adopt a high-precision design to ensure stable transmission and low noise. The motor should choose a well-known brand product to ensure sufficient power and stable operation.

4.3 Consider Automation Level and Operation Convenience

With the development of technology, modern feed pellet machines are becoming more and more automated. High-end models are equipped with PLC touch screen control systems, which can realize automatic control of the production process, such as automatic adjustment of feeding amount, pressure and temperature. Some models also have functions such as automatic die change and automatic lubrication, which are easy to operate and save labor costs. For breeders who have no professional operation experience, it is recommended to choose a feed pellet machine with simple operation and a friendly man-machine interface.

4.4 Pay Attention to After-Sales Service and Warranty

The feed pellet machine is a mechanical equipment that needs long-term operation, and after-sales service is particularly important. When purchasing, you should choose a brand with perfect after-sales service, such as providing on-site installation and commissioning, technical training, and timely supply of spare parts. At the same time, pay attention to the warranty period of the machine. Generally, the warranty period of the feed pellet machine is 1 year, and some brands can provide a 2-year warranty for key components, which can reduce the maintenance cost and use risk of the machine.

5. Investment Return Analysis of Feed Pellet Machine: A Profitable Breeding Helper

For many breeders and entrepreneurs, the investment return of the feed pellet machine is an important factor to consider. In fact, the feed pellet machine has the characteristics of low investment and high return, and the return cycle is relatively short. The specific investment return analysis is as follows:

5.1 Investment Cost

The investment cost of the feed pellet machine mainly includes the equipment cost, raw material cost, electricity cost and labor cost. Among them, the equipment cost varies according to the model: small feed pellet machines (suitable for individual breeders) cost 300-1000 US dollars; medium-sized models (suitable for processing services) cost 1000-5000 US dollars; large industrial models (suitable for feed factories) cost 10000-50000 US dollars. In addition, the raw material cost is about 100-200 US dollars per ton, the electricity cost per ton of feed is 5-12 US dollars, and the labor cost is relatively low (small models can be operated by one person).

5.2 Profit Model

There are three main profit models for feed pellet machines: first, self-use by breeders, saving feed costs. A small feed pellet machine can process 500-2000 kg of feed per day, and the annual feed cost can be saved by tens of thousands of US dollars, and the investment can be recovered in 3-6 months. Second, feed processing services. For medium-sized feed pellet machines with a daily output of 5-20 tons, the daily profit can reach 100-500 US dollars, and the investment can be recovered in 2-5 months. Third, batch production and sales of pellet feed. Large feed pellet machines have a daily output of more than 20 tons, and the profit per ton of feed is 50-100 US dollars, with a monthly income of 10000-30000 US dollars.

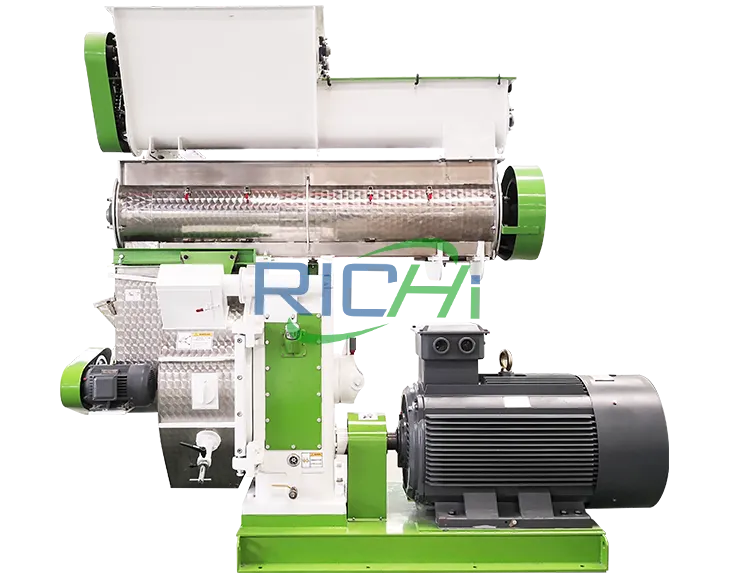

6. RICHI Feed Pellet Machine: Your Trusted Partner in Efficient Breeding

As a professional manufacturer of feed pellet machines, RICHI Machinery has been committed to providing high-quality, efficient and reliable feed processing equipment for global breeders. RICHI feed pellet machine has the following advantages:

- Complete models and flexible selection: RICHI provides feed pellet machines with a production capacity of 1-42 t/h and a power of 22-315 kw, covering all types of breeding and production needs. The pellet size can be adjusted between 1.5-12 mm, and the conditioner is equipped with molasses and steam adding functions to meet the needs of different feed formulas.

- High efficiency and energy saving: Adopting classic gear-driven technology, no slipping, ensuring stable output and low noise. The optimized die design improves the pellet forming rate and reduces energy consumption by 15% compared with similar products.

- Safe and hygienic: It adopts CE certification standard design, and the optional stainless steel conditioner ensures the hygiene and safety of feed. The high-temperature processing process can effectively kill harmful bacteria and meet the food safety requirements of the breeding industry.

- Friendly operation and easy maintenance: The hydraulic system is adopted for die change and roller adjustment, which is fast and accurate. The optional automatic lubrication system and die & roller lifting device save labor. The on-site touch screen control makes the operation simple and easy to learn.

- Perfect after-sales service: Provide 24-hour technical consultation response, on-site installation and commissioning, operator training and other services. The whole machine has a 1-year warranty, and vulnerable parts have a 3-month warranty, ensuring that users have no worries about use.

Conclusion

In the context of the increasing scale and refinement of the breeding industry, the feed pellet machine has become a key equipment to improve breeding efficiency and reduce costs. Whether you are an individual breeder, a farm operator or an entrepreneur engaged in feed processing, choosing a suitable feed pellet machine can bring you considerable economic benefits. RICHI feed pellet machine, with its high-quality products and perfect services, is committed to helping global users realize efficient and profitable breeding. If you want to know more about the model, price and technical parameters of the feed pellet machine, welcome to contact us for detailed consultation!

Please feel free to contact RICHI if you have any needs. RICHI Machinery will be happy to assist you.(this link)