With the rapid development of modern livestock and poultry farming, feed quality and production efficiency have become key factors affecting profitability. As a result, more investors and feed producers are actively searching for an animal feed pellet machine for sale that can deliver consistent pellet quality, stable output, and long-term operational reliability. Whether for cattle, poultry, sheep, or mixed livestock feed, pelletizing technology plays a vital role in today’s feed industry.

Why Pelletized Feed Is Widely Used in Animal Nutrition

Pellet feed has gradually replaced traditional mash feed in many regions due to its clear advantages. Pelletized feed improves feed conversion efficiency, reduces waste during transportation and feeding, and ensures a more balanced nutrient intake for animals. In addition, pellets are easier to store and transport, making them especially suitable for commercial farms and feed mills.

To achieve these benefits, reliable feed processing equipment is essential. This is why selecting the right animal feed pellet machine is not just a purchasing decision, but a long-term investment in feed quality and production stability.

Key Components of an Animal Feed Pellet Production System

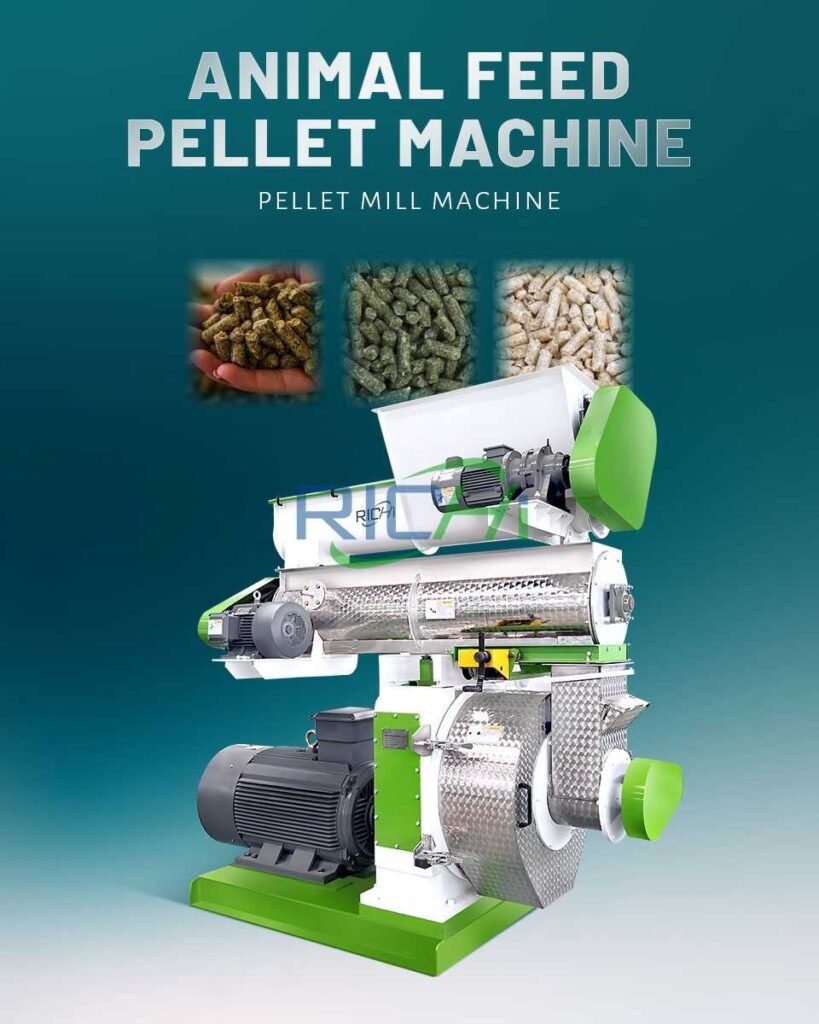

A typical animal feed pelletizing system includes raw material crushing, mixing, pelletizing, cooling, and screening. Among these stages, the pellet mill is the core machine that determines pellet density, durability, and output capacity. High-quality pellet machines are designed with optimized die and roller structures, stable transmission systems, and durable materials to ensure continuous operation under heavy loads.

When evaluating equipment options, many buyers also pay close attention to the feed pellet mill machine price, as it reflects not only machine size and capacity but also configuration level, material quality, and long-term maintenance costs.

Anchor text: feed pellet mill machine price

Factors That Influence Equipment Selection

Choosing the right animal feed pellet machine depends on several practical factors. Production capacity is usually the first consideration, as small farms and large feed mills have very different output requirements. Raw material types are another important factor, since processing corn, soybean meal, grass, or mixed formulas may require different machine configurations.

Automation level and future expansion plans should also be considered. Some producers start with semi-automatic systems and later upgrade to fully automated feed production lines. For investors who want to understand different configurations and application scenarios in more detail, you can click here to read https://www.richimanufacture.com/10tph-animal-feed-processing-plant-in-uzbekistan/

Applications Across Different Livestock Sectors

Animal feed pellet machines are widely used in cattle, poultry, sheep, goat, and other livestock feed production. By adjusting die size and process parameters, the same pelletizing equipment can often be adapted to different feed formulas. This flexibility makes pellet machines especially attractive for regions with diversified animal farming structures.

In many developing and emerging markets, local feed producers are investing in pelletizing equipment to reduce reliance on imported feed and improve cost control. A reliable pellet machine helps ensure stable feed supply while maintaining consistent nutritional standards.

The Importance of Equipment Quality and Manufacturer Support

While initial purchase cost is important, experienced buyers understand that long-term performance matters more. A well-designed pellet machine reduces downtime, minimizes spare parts replacement, and lowers energy consumption over time. Just as important is the support provided by the manufacturer, including technical guidance, installation assistance, and after-sales service.

Working with an experienced equipment supplier like RICHI Machinery allows investors to access not only high-quality pellet machines but also professional support throughout the entire project lifecycle, from equipment selection to plant commissioning.

Conclusion

Finding the right animal feed pellet machine for sale requires a balance between capacity, application requirements, budget, and long-term production goals. By understanding pelletizing technology, evaluating real production needs, and choosing a reliable supplier, feed producers can build a solid foundation for efficient and sustainable feed manufacturing. As global demand for high-quality animal feed continues to grow, pelletizing equipment will remain a key asset in modern feed processing operations.