A 20T/H animal feed production line is a fully automated system designed to produce high-quality animal feed pellets at a rate of 20 metric tons per hour. This state-of-the-art facility caters to the diverse needs of livestock, poultry, and aquaculture industries, ensuring a consistent supply of nutritious feed for various animal species.

Applications and Market Analysis

The global animal feed industry is experiencing unprecedented growth, driven by the rising demand for animal-based products and the need for efficient and sustainable feed production methods.

A 20T/H animal feed production line plays a pivotal role in meeting this demand, catering to both large-scale commercial operations and medium-sized feed mills.

According to a report by Grand View Research, the global animal feed market size was valued at $408.7 billion in 2021 and is projected to reach $492.2 billion by 2027, exhibiting a compound annual growth rate (CAGR) of 4.3% during the forecast period.

This growth is fueled by factors such as population growth (projected to reach 9.7 billion by 2050 according to the United Nations), urbanization, and the increasing demand for protein-rich diets.

Profit Point Analysis

Investing in a 20T/H animal feed production line offers numerous profit opportunities for feed manufacturers. By streamlining the production process and maximizing efficiency, these lines reduce operational costs by up to 25%, increase output by 20-30%, and improve product quality by minimizing waste and ensuring consistent nutrient profiles.

Additionally, the ability to produce a diverse range of feed types caters to various market segments, expanding revenue streams and enhancing profitability by an estimated 15-20%.

Process Flow and Industry Impact

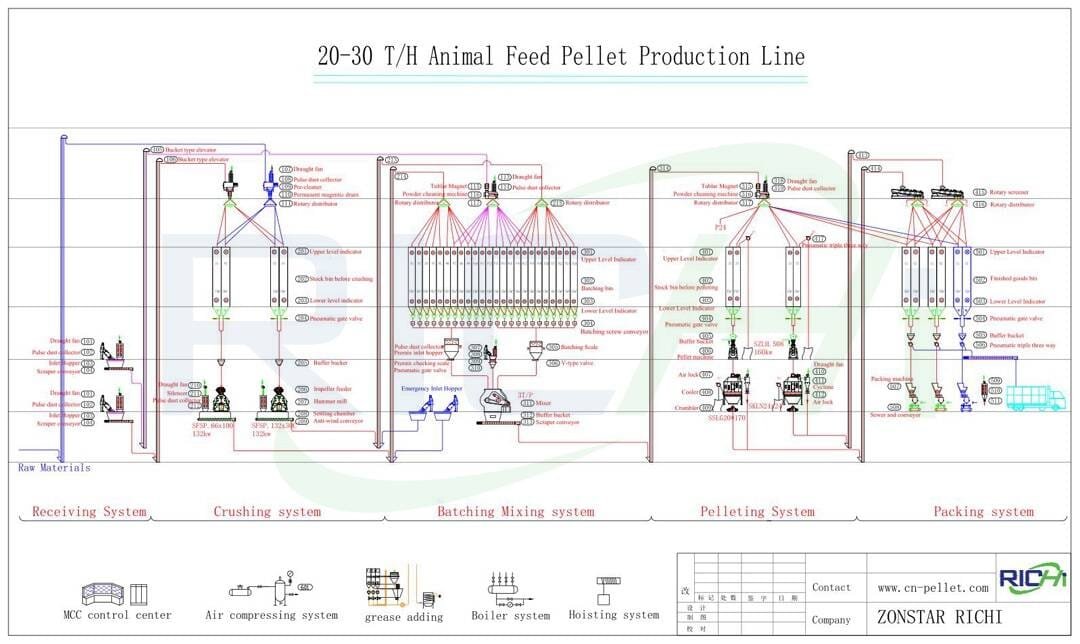

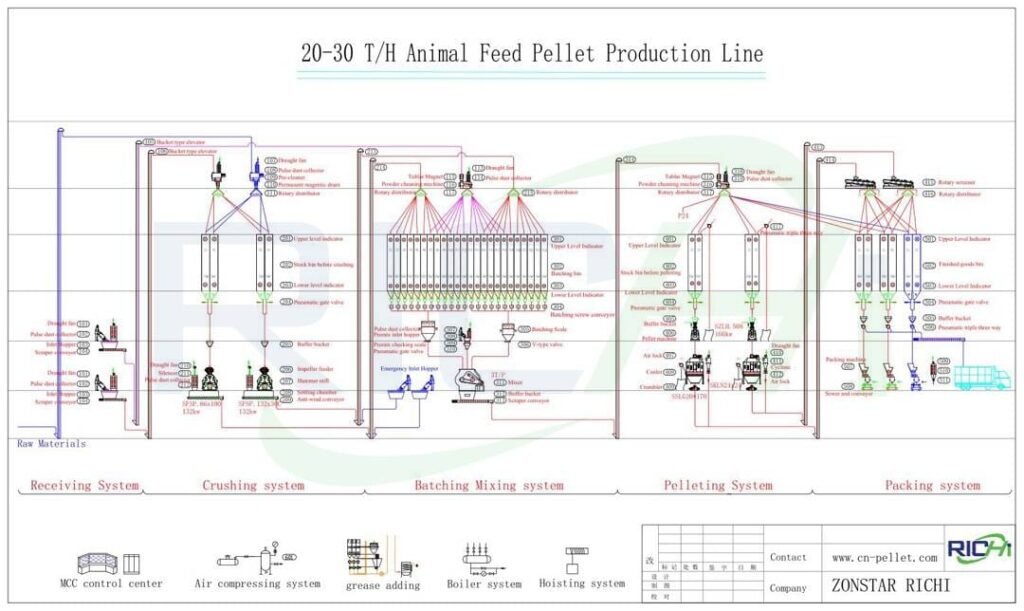

The process flow of a 20T/H animal feed production line typically involves the following stages:

- Raw material receiving and cleaning

- Grinding and crushing (using hammer mills with a capacity of 5-10 TPH)

- Batching and mixing (in horizontal or vertical mixers with a capacity of 3-5 tons)

- Conditioning and pelleting (using ring die or flat die pellet mills with a die area of 0.5-1.2 m²)

- Cooling (in counterflow or octagonal coolers with a capacity of 20-30 TPH)

- Crumbling (in crumblers with a capacity of 15-25 TPH)

- Screening and sifting (using rotary screeners with a capacity of 20-30 TPH)

- Coating and fat spraying (optional, with a capacity of 15-25 TPH)

- Packaging and bagging (with a capacity of 10-20 bags per minute)

This streamlined process ensures consistent quality (with nutrient variations less than 5%), efficient resource utilization (energy consumption reduced by 15-20%), and adherence to industry standards (meeting regulations like FAMI-QS, GMP+, and HACCP), contributing to the overall sustainability and profitability of the animal feed industry.

Choosing the Right Supplier: RICHI Machinery

When it comes to selecting a reliable supplier for a 20T/H animal feed production line, RICHI Machinery stands out as a trusted partner. With over 27 years of experience in the feed machinery industry, RICHI Machinery has established itself as a leading provider of turnkey solutions for feed mills worldwide, with over 3,000 successful projects in more than 121 countries.

Key Advantages of Choosing RICHI Machinery:

- Customization: RICHI Machinery offers customized solutions tailored to specific customer requirements, ensuring optimal performance and efficiency. Their engineering team can design and configure the production line to meet specific output capacities (ranging from 5 TPH to 50 TPH), raw material compositions, and feed types.

- Turnkey Projects: From design and engineering to installation and commissioning, RICHI Machinery provides end-to-end turnkey services, minimizing project complexities and ensuring seamless integration of all components.

- Global Reach: With a presence in over 121 countries and a network of regional offices and service centers, RICHI Machinery has a proven track record of delivering high-quality solutions to clients across the globe, ensuring timely support and maintenance.

- Comprehensive Support: RICHI Machinery provides comprehensive after-sales support, including on-site training, preventive maintenance programs, and a reliable spare parts supply chain, ensuring seamless operations and maximizing uptime.

- Advanced Technology: RICHI Machinery incorporates cutting-edge technologies, such as advanced control systems, energy-efficient equipment, and innovative process optimization techniques, ensuring optimal performance and sustainability.

By partnering with RICHI Machinery, feed manufacturers can leverage the company’s expertise, cutting-edge technology, and commitment to excellence, ensuring a successful and profitable venture with a 20T/H animal feed production line.

Frequently Asked Questions (FAQs)

Common raw materials include grains (corn, wheat, barley, oats, sorghum), oilseed meals (soybean meal, rapeseed meal, cottonseed meal), and other ingredients like fish meal, rice bran, wheat bran, grass meal, vitamins, and minerals. The specific composition can vary based on the target animal species and nutritional requirements.

Yes, these production lines are versatile and can produce various types of animal feed, including poultry feed (broilers, layers) with a typical protein content of 18-22%, livestock feed (cattle, pigs, goats) with a protein content of 12-18%, and aquaculture feed (fish, shrimp) with a protein content of 25-40%.

The main equipment includes hammer mills for grinding (with a capacity of 5-10 TPH), batching systems and ingredient bins (with a capacity of 10-20 tons), horizontal or vertical mixers (with a capacity of 3-5 tons), ring die or flat die pellet mills with conditioners (with a die area of 0.5-1.2 m²), counterflow or octagonal coolers (with a capacity of 20-30 TPH), crumblers (with a capacity of 15-25 TPH), rotary screeners/sifters (with a capacity of 20-30 TPH), and packaging/bagging machines (with a capacity of 10-20 bags per minute).

Quality and consistency are achieved through precise control of the production process, including accurate batching (with a weighing accuracy of ±0.5%), efficient mixing (with a coefficient of variation less than 5%), optimal conditioning (with a moisture content of 14-18%) and pelleting (with a pellet durability index of 95-98%), uniform cooling (with a temperature differential of less than 5°C), and effective screening/sifting (with a sieve aperture of 2-4 mm).

Additionally, regular maintenance and calibration of equipment, as well as adherence to quality control protocols (such as HACCP and ISO 22000), are crucial.

Yes, most reputable suppliers like RICHI Machinery offer modular and scalable solutions that can be expanded or upgraded to accommodate future growth and changing production requirements.

For instance, additional parallel process lines can be added to increase the overall capacity, or individual components (such as larger pellet mills or coolers) can be replaced to enhance throughput and efficiency.

Conclusion

In the ever-evolving animal feed industry, a 20T/H animal feed production line represents a game-changing investment for feed manufacturers.

By leveraging advanced technology, streamlined processes, and customized solutions from trusted suppliers like RICHI Machinery, businesses can unlock new levels of efficiency, profitability, and sustainability.

With the global animal feed market projected to reach $492.2 billion by 2027 at a CAGR of 4.3%, embracing the power of a 20T/H animal feed production line positions your business at the forefront of this dynamic industry, ensuring long-term growth and competitiveness.