The Straw Pellet Making Machine is primarily designed to convert agricultural residues, particularly straw, into compact biomass pellets. However, a common question among energy producers and biomass enthusiasts is whether this versatile equipment can also be used to produce fuel pellets from other materials. This article explores the potential of using Straw Pellet Making Machines for fuel pellet production, considering the similarities, differences, and necessary adaptations.

Similarities Between Straw Pellets and Fuel Pellets

To understand the potential for using a Straw Pellet Making Machine for fuel pellets, it’s important to recognize the similarities between the two products:

- Pelletizing Process: The basic principle of compressing materials into pellets is similar for both straw and other biomass fuel pellets.

- End Use: Both straw pellets and fuel pellets are primarily used as a source of renewable energy for heating and power generation.

- Physical Characteristics: The size, shape, and density requirements are often similar for various types of biomass fuel pellets.

These similarities suggest that there is significant potential for adapting the Straw Pellet Making Machine for various types of fuel pellet production.

Types of Fuel Pellets Potentially Suitable for Production

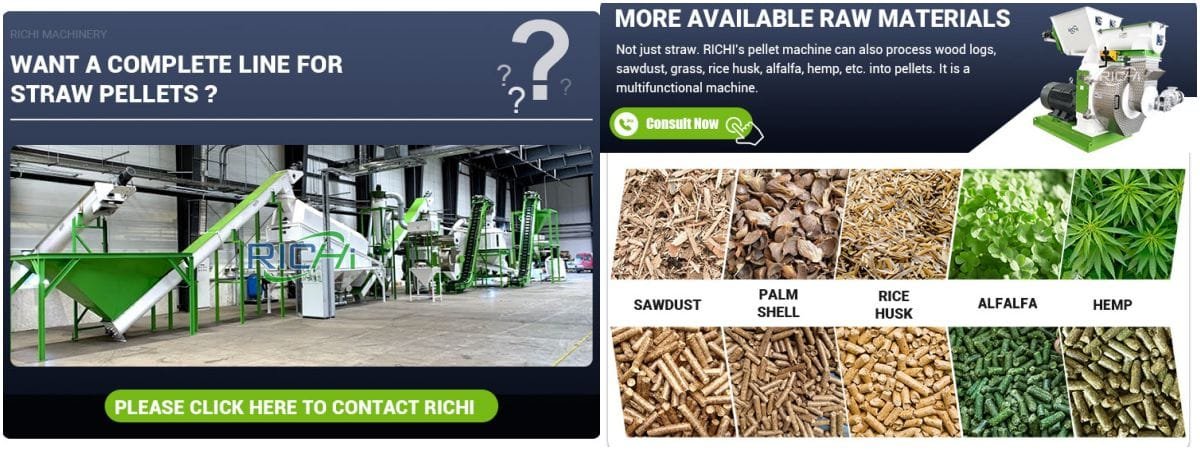

Several types of fuel pellets could potentially be produced using a Straw Pellet Making Machine:

- Wood Pellets: Made from sawdust, wood chips, or other wood waste.

- Agricultural Residue Pellets: Including corn stalks, sugarcane bagasse, or rice husks.

- Energy Crop Pellets: From crops specifically grown for energy production, such as miscanthus or switchgrass.

- Mixed Biomass Pellets: Combining various biomass sources for optimal fuel characteristics.

Adaptations and Considerations

While the Straw Pellet Making Machine is well-suited for producing straw pellets, some adaptations may be necessary for processing other types of fuel pellets:

- Grinding Mechanism: Different biomass materials may require adjustments to the grinding process to achieve the optimal particle size for pelletization. Harder materials like wood might need a more robust grinding system.

- Moisture Content Management: Various biomass sources have different natural moisture contents. The drying and conditioning processes may need to be adjusted to achieve the ideal moisture level for pelletization (typically 10-15%).

- Die and Roller Configuration: The die holes and roller pressure may need to be optimized for different materials to achieve the desired pellet density and durability. Some materials may require different die thickness or hole diameter.

- Binding Agents: While straw often has sufficient natural lignin to bind into pellets, other materials might require the addition of natural binders. The machine may need to be equipped with a system for adding and mixing binding agents if necessary.

- Cooling and Drying: Different biomass materials may have varying cooling and drying requirements to achieve the optimal final moisture content and pellet stability.

- Dust Collection: Some materials may produce more dust during processing, requiring enhanced dust collection systems. (Related post: fuel pellet machine)

Advantages of Using Straw Pellet Making Machines for Fuel Pellets

Adapting Straw Pellet Making Machines for various fuel pellets offers several advantages:

- Versatility: The ability to process multiple types of biomass increases the machine’s utility and adaptability to market demands.

- Cost-Effectiveness: Utilizing one machine for multiple biomass sources can be more economical than investing in separate equipment for each type.

- Local Resource Utilization: The adaptability allows for the use of locally available biomass resources, reducing transportation costs and environmental impact.

- Seasonal Flexibility: The ability to switch between different biomass sources allows for year-round production, accommodating seasonal availability of various materials.

- Market Responsiveness: Producers can quickly adapt to changing market demands for different types of fuel pellets.

Challenges and Considerations

While Straw Pellet Making Machines can often be adapted for fuel pellet production, there are challenges to consider:

- Material Properties: Different biomass materials have varying fiber structures, densities, and binding properties, which may affect pellet quality. Extensive testing may be required to optimize the process for each material.

- Energy Consumption: Some materials may require more energy to process than straw, potentially affecting overall efficiency and cost-effectiveness.

- Wear and Tear: Certain biomass materials, particularly those with higher silica content or hardness, may cause increased wear on machine components.

- Quality Standards: Fuel pellets often need to meet specific quality standards for commercial use. Ensuring consistent quality across different materials can be challenging.

- Regulatory Compliance: Depending on the intended use and market, fuel pellets may need to meet certain regulatory standards, which may require additional quality control measures.

Case Studies and Expert Opinions

Several case studies demonstrate the successful adaptation of Straw Pellet Making Machines for other fuel pellets:

- A biomass energy company in Germany reported successfully using their straw pellet machine to produce wood pellets after minor modifications to the grinding and die systems.

- A cooperative of farmers in India adapted their straw pellet machine to process rice husk pellets, creating a valuable product from what was previously considered waste.

- An energy crop producer in the United States used a modified straw pellet machine to process miscanthus grass into high-quality fuel pellets.

- An expert in biomass processing commented, “With the right adjustments, most modern straw pellet machines can handle a variety of biomass materials. The key is understanding the properties of each material and optimizing the process accordingly.”

Conclusion

The Straw Pellet Making Machine demonstrates significant potential for processing various types of fuel pellets beyond just straw. Its adaptability to different biomass materials makes it a versatile tool in the renewable energy sector. While some modifications and optimizations may be necessary depending on the specific biomass material, the core technology of these machines is well-suited to the production of a wide range of fuel pellets.

For those considering using a Straw Pellet Making Machine for diverse fuel pellet production, it’s crucial to conduct thorough testing with the intended materials, consult with equipment manufacturers about necessary modifications, and ensure compliance with relevant quality standards and regulations.

As the demand for renewable energy sources continues to grow, the versatility of equipment like the Straw Pellet Making Machine becomes increasingly valuable. Its ability to process various biomass materials into high-quality fuel pellets not only enhances the machine’s utility but also contributes to more flexible and sustainable energy production systems.

Ultimately, the successful adaptation of Straw Pellet Making Machines for diverse fuel pellet production can play a significant role in advancing the use of biomass as a renewable energy source, supporting local economies, and contributing to global efforts in reducing reliance on fossil fuels.