Before the pellet equipment mold is made use of, the compression ratio need to be changed and calculated. This is generally to adjust the diameter of the mold, the thickness, the taper and reaming level of the bell mouth, the product of the mold, the firmness of the mold, and also various products, there are different mold compression ratios.

So we have to readjust as well as compute according to our real situation, so what is the modification estimation approach of the pellet maker mold compression ratio?

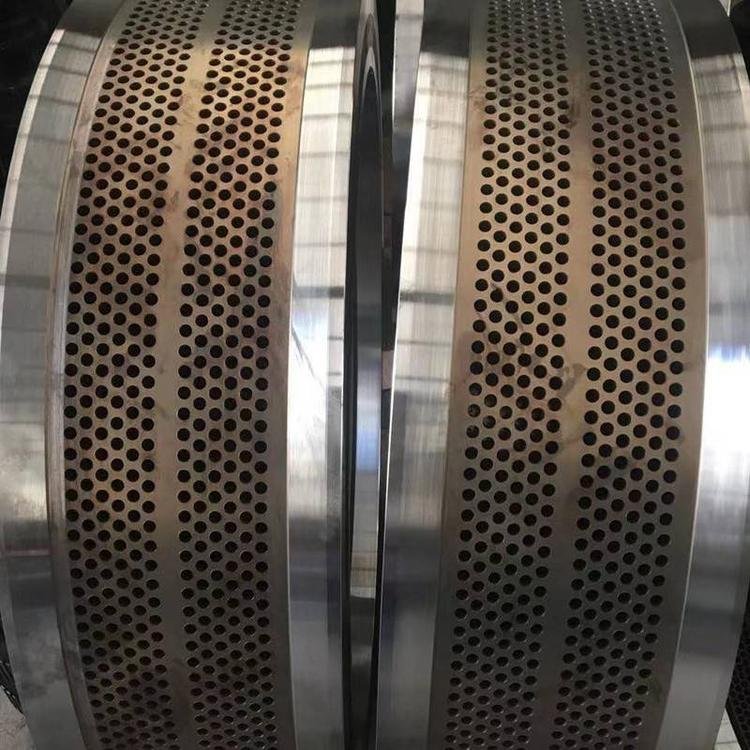

Compression Ratio Of Pellet Maker Mold

The compression ratio of the pellet equipment die describes the ratio of the effective length of the die opening of the die to the die size, and also is an index reflecting the extrusion toughness of the pellet maker.

Pellet machine mold compression ratio = mold opening size/ efficient functioning size of mold hole

For a mold with a straight hole, the reliable length of the mold hole is the complete density of the mold, as well as the tiny size is the diameter of the mold hole itself.

Assumption: The size of the die hole is 6mm, and also the density of the ring die is 45mm

Compression ratio= 6/45= 1:7.5.

The ring mode compression ratio is 1:7.5.

For the release step hole as well as the outer conical hole, the efficient length of the die hole is the total density of the mold minus the size of the release opening or the size of the outer tapered opening, and the aperture of the small diameter section is the aperture for calculating the compression ratio.

Presumption: the size of the ring die opening is 8mm, the die density is 66mm, and the release opening is 18mm.

Compression ratio= 8/( 66-18)= 1:6.

The ring mode compression ratio is 1:6.

Compression ratio is a ratio. For the exact same compression ratio, its aperture and effective working size may be various.

How To Pick an Appropriate Mold Compression Ratio?

1. The aperture dimension and result of the mold are closely pertaining to the internal diameter of the pellet maker mold and also the composition of the raw materials. The typical aperture of 8-10 mm typically made use of in the industry is called traditional data.

The pellet machine larger than 10 mm needs better pressure for molding., Reasonably talking, the wear is additionally large, individuals generally call it a biomass rod making equipment or a rod making machine.

2. The effective density of the mold is very essential for the molding of basic materials.

If the mold is too thick, the molding time of the raw material is much longer, the thickness of the fragments is relatively huge, the extrusion is harder, the mold is slim as well as easy to break, as well as the thickness of the particles is fairly tiny.

Journalism temperature is reduced, the output is high, yet the molding price is low or the molding is poor.

3. The compression ratio of rough tools is established according to the raw products. The compression ratio of poplar wood is 1:6, the compression ratio of ache wood is 1:7, the compression ratio of difficult wood is 1:5, as well as the compression ratio of shavings is 1.: 5.5, the compression ratio of corn stalk is 1:6.5.

From these simple figures, the compression ratio of various basic materials is various. The more challenging the raw product, the smaller sized the compression ratio, and also the cosy the raw product, the higher the compression ratio.

That is to claim, the more cosy the raw material, the much easier it is to be formed. The more fluffy raw material contains much more fibers, and also the even more fiber-containing products are less complicated to form.

4. Each small opening directly has 6 mm, 8 mm, and 10 mm. This 1 represents the size of each little hole. If the size of the ring die opening is 8 mm, then this 1 represents 8, As well as 6 stands for the effective aperture.

The reliable aperture amounts to the diameter of the hole multiplied by the effective aperture size, which is 6 * 8= 48, which is 8:48, 8:48 is streamlined to 1:6, 1: 6 is the compression ratio of poplar wood. It is converted by doing this.

The quality of the biomass pellet equipment’s result relies on the compression ratio of the ring die. However if the client does not have high demands for the molding rate of your pellets, then you can properly Reduce the compression ratio, which can not just enhance the result, but also lower the life span of the mold and also journalism wheel.

5. Roughness is also a crucial indicator to measure the quality of ring die. Under the very same compression ratio, the greater the roughness value, the higher the extrusion resistance of the sawdust fragments, as well as the more difficult it is to discharge the product.

Excessive roughness additionally influences the top quality of the particle surface. The ideal roughness worth should be 0.8-1.6. in between.

What To Do If The Mold Compression Ratio Is Too Huge?

1. Experienced operators will certainly change the moisture content of the raw materials or change the void between the ring molding rollers, as well as the pellets can be efficiently discharged without altering the compression ratio. The process requires to be taped as well as examined step by step.

2. Additionally, the 2nd pressurization can make the mold with a bigger compression ratio smaller, yet modifying the ring mold will impact the hardness of the ring mold, so it requires to be figured out according to the actual wear of the mold.

The roughness of the die opening of the pellet machine is likewise a vital sign to measure the top quality of the mold, as well as the suitable roughness worth must be in between 0.8-1.6.

Under the exact same compression ratio, the larger the roughness value, the greater the bit extrusion resistance, and the harder it is to release the product. Excessive roughness also impacts the top quality of the particle surface area.